KT型空调泵概述:

KT型空调泵,是为中央空调设计的单级离心泵,该型泵的流量从11米3/小时至1920米3/小时,扬程从6.8米至100米。该型泵的工作温度为-10℃至80℃;泵的工作压力(包括进口压力)可达1.6MPa(泵入口直径≤200)和2MPa (泵入口直径≥250)。

该型泵适用于各种制冷系统,特别适合于中央空调系统等要求泵承受压力比较高的场合,也可用于工厂、矿山、电站水利工程的给水或排水。

该型泵效率高,节约能源;泵噪音低,振动小;在性能、结构及尺寸方面采用ISO2858标准,完全可以替代进口产品。

KT型空调泵用途:

1,传送介质:清水或物理化学性质类似清水的液体,

2该泵适用于各种制冷系统,特别适合于中央空调系统等要求泵承受压力比较高的场合

3,工厂、矿山、电站水利工程的给水或排水,

4,中央空调冷却系统。

5,高楼给水。

KT型空调泵特点:

1,后开式结构,检修方便 · 运转稳定,可靠,寿命长

2, 低噪音电机,比同类产品约低10dB · 出厂前均作2.4MPa耐压试验,确保使用安全 结构说明:

3,后开式结构,检修方便,无需拆卸泵体及进出水管

4,通用性广,只有4种规格的轴、轴承、联轴器盖,减少了备品备件,便于检修管理

5,叶轮前后均有密封环,叶轮后盖板设平衡孔平衡泵的轴向力

6,耐磨机械密封装置,保证在较高水压下不漏水

7,青铜叶轮,不锈钢轴,进口轴承

8,轴承润滑结构分干油脂润滑及湿机械油润滑二种

9,KT型空调泵,是为中央空调设计的单级离心泵。

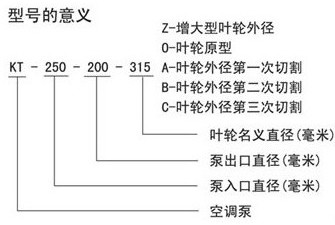

KT型空调泵型号意义:

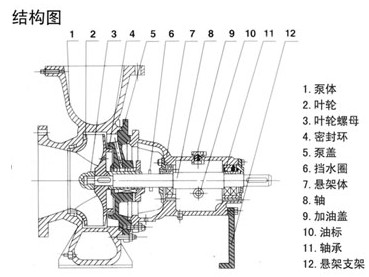

KT型空调泵型号结构图:

KT型空调泵基本参数:

型号 |

叶轮

型式 |

流量 |

扬程

m |

转速

(r/min) |

功率 ( kw) |

效率 % |

必需汽蚀余量

(m) |

总质量 ( kg) |

(M3/h) |

轴功率 |

电机功率 |

|

|

|

86-65-125 |

O |

30

50

60 |

22.5

20

18 |

2900 |

2.87

3.63

3.98 |

5.5 |

64

75

74 |

3.0

3.0

3.5 |

140 |

A |

28.7

47.9

57.4 |

20.6

18.3

16.5 |

2.56

3.27

3.56 |

5.5 |

63

73

72.5 |

3.0

3.0

3.3 |

140 |

B |

26.1

43.6

52.3 |

17.1

15.2

13.7 |

2.01

2.59

2.84 |

4 |

60.5

69.5

68.5 |

3.0

3.0

3.1 |

130 |

C |

23.1

38.6

46.3 |

13.4

11.9

10.7 |

1.45

1.91

2.09 |

3 |

58

65.5

64.5 |

3.0

3.0

3.0 |

110 |

80-65-160 |

O |

30

50

60 |

36

32

29 |

2900 |

4.82

5.97

6.59 |

7.5 |

61

73

72 |

2.5

2.5

3.0 |

160 |

A |

28.2

46.9

56.3 |

31.7

28.2

25.5 |

4.05

5.07

5.59 |

7.5 |

60

71

70 |

2.5

2.5

2.8 |

160 |

B |

25.9

43.2

51.9 |

26.9

23.9

21.7 |

4.21

4.20

4.63 |

5.5 |

59

67

66 |

2.5

2.5

2.6 |

155 |

C |

24.1

40.1

48.2 |

23.2

20.6

18.7 |

2.67

3.52

3.89 |

5.5 |

67

64

63 |

2.5

2.5

2.5 |

155 |

80-50-200 |

O |

30

50

60 |

53

50

47 |

2900 |

7.87

9.87

10.8 |

15 |

55

69

71 |

2.5

2.5

3.0 |

235 |

A |

28.0

46.9

55.9 |

46.0

43.4

40.8 |

6.42

8.21

8.93 |

11 |

54.5

67

69.5 |

2.5

2.5

2.7 |

225 |

B |

25.6

42.7

51.2 |

38.6

36.4

34.2 |

5.02

6.40

6.96 |

11 |

53.5

66

68.5 |

2.5

2.5

2.53 |

225 |

C |

23.5

39.2

47.1 |

32.6

30.8

28.9 |

3.98

5.09

5.45 |

7.5 |

52.5

64.5

58 |

2.5

2.5

2.5 |

165 |

80-50-250 |

O |

30

50

60 |

84

80

75 |

2900 |

13.2

17.3

19.2 |

22 |

52

63

64 |

2.5

2.5

3.0 |

345 |

|

A |

28.3

47.2

56.6 |

74.9

71.3

66.8 |

|

11.0

14.6

16.1 |

22 |

52.3

62.6

64 |

2.5

2.5

2.8 |

345 |

|

B |

26.6

44.4

53.3 |

66.2

63.1

59.1 |

|

9.1

12.3

13.4 |

18.5 |

52.7

62.2

64 |

2.5

2.5

2.6 |

315 |

|

C |

23.8

39.6

47.5 |

52.7

50.2

47.0 |

|

6.43

8.90

9.59 |

15 |

53

60.8

63.5 |

2.5

2.5

2.5 |

280 |

80-50-315 |

O |

30

50

60 |

128

125

123 |

2900 |

25.5

31.5

35.3 |

37 |

41

54

57 |

2.5

2.5

3.0 |

440 |

|

A |

28.0

46.7

56.0 |

112

109

107 |

|

20.7

25.9

28.8 |

37 |

41

53.5

56.7 |

2.5

2.5

2.7 |

440 |

|

B |

26.3

43.8

52.6 |

98.3

96.0

94.4 |

|

17.2

21.6

24.0 |

30 |

41

53

56.3 |

2.5

2.5

2.63 |

425 |

|

C |

24.3

40.5

48.6 |

83.9

81.9

80.6 |

|

13.5

17.2

19.0 |

22 |

41

52.5

56 |

2.5

2.5

2.5 |

370 |

100-80-125 |

O |

60

100

120 |

24

20

16.5 |

2900 |

2.86

7.0

7.28 |

11 |

67

78

74 |

4.0

4.5

5.0 |

215 |

|

A |

56.6

94.2

113 |

21.3

17.8

14.7 |

|

5.17

6.25

6.45 |

11 |

63.5

73

70 |

4.0

4.4

4.8 |

215 |

|

B |

53.5

89.2

107 |

19.1

15.9

13.1 |

|

4.64

5.52

5.89 |

7.5 |

60

70

65 |

4.0

4.3

4.65 |

165 |

|

C |

47.9

79.1

95.0 |

15.0

12.5

10.3 |

|

3.57

4.22

4.28 |

5.5 |

54.5

64

62.5 |

4.0

4.2

4.4 |

155 |

100-80-160 |

O |

60

100

120 |

36

32

28 |

2900 |

8.42

11.2

12.2 |

15 |

70

78

75 |

3.5

4.0

5.0 |

260 |

|

A |

56.9

94.8

114 |

32.4

28.8

25.2 |

|

7.19

9.58

10.5 |

15 |

69.7

77.5

74.2 |

3.5

3.97

4.5 |

260 |

|

B |

53.4

89.0

107 |

28.5

25.4

222 |

|

5.99

8.02

8.75 |

11 |

69.3

76.6

73.8 |

3.5

3.77

4.1 |

250 |

|

C |

50.6

84.4

101 |

25.6

22.8

19.9 |

|

5.12

6.89

7.48 |

11 |

69

76

73.5 |

3.5

3.65

3.93 |

250 |

100-65-200 |

O |

60

100

120 |

54

50

47 |

2900 |

13.6

17.9

19.9 |

22 |

65

76

77 |

3.0

3.6

4.8 |

345 |

|

A |

56.4

94.1

113 |

47.8

44.2

41.6 |

|

11.3

14.8

16.6 |

22 |

65

76.5

77 |

3.0

3.45

4.3 |

345 |

|

B |

53.5

89.1

107 |

42.9

39.7

37.3 |

|

9.6

12.9

14.3 |

18.5 |

65

74.5

76 |

3.0

3.35

3.6 |

315 |

|

C |

50.5

84.2

101 |

38.3

35.4

33.3 |

|

8.09

11.1

12.2 |

15 |

65

73

75 |

3.0

3.25

3.6 |

280 |

100-65-250 |

O |

60

100

120 |

80

87

74.5 |

2900 |

23.4

30.3

33.3 |

37 |

61

72

73 |

3.5

3.8

4.8 |

450 |

|

A |

56.0

93.3

112 |

75.8

69.7

64.9 |

|

19.4

25.6

28.1 |

37 |

59.5

69.3

70.5 |

3.5

3.7

4.35 |

450 |

|

B |

52.2

87.1

104 |

65.9

60.6

56.5 |

|

16.6

21.8

24.0 |

30 |

56.5

66.1

67 |

3.5

3.6

4.0 |

435 |

|

C |

48.5

80.8

96.6 |

56.8

52.2

48.6 |

|

14.1

18.3

20.1 |

30 |

53

62

67 |

3.5

3.5

3.75 |

435 |

100-65-315 |

O |

60

100

120 |

133

125

118 |

2900 |

39.6

51.6

57.5 |

75 |

55

60

67 |

3.0

3.6

4.2 |

840 |

|

A |

56

93.3

112 |

116

109

103 |

|

32.1

42.5

47.5 |

55 |

55

65.2

66 |

3.0

3.45

3.95 |

700 |

|

B |

52.6

87.6

105 |

102

96

90.6 |

|

26.6

35.5

39.9 |

45 |

55

64.5

65 |

3.0

3.32

3.70 |

585 |

|

C |

48.5

81.0

97.1 |

87.2

81.9

77.3 |

|

21.0

28.7

32.0 |

37 |

55

63

64 |

3.0

3.2

3.5 |

510 |

125-80-160 |

Z |

105

174

209 |

42.8

38

33.3 |

2900 |

16.9

22.6

24.6 |

30 |

72

80

77 |

5.6 |

400 |

|

O |

96

160

192 |

36

32

28 |

|

13.1

17.5

19.0 |

22 |

72

80

77 |

5.6 |

340 |

|

A |

89.8

150

180 |

31.5

28

24.5 |

|

11.0

14.7

16.0 |

18.5 |

70

78

75 |

5.6 |

300 |

|

B |

83.1

139

166 |

27

24

21 |

|

8.99

11.9

13.0 |

15 |

68

76

73 |

5.6 |

275 |

125-80-200 |

Z |

105

175

210 |

66

60

55.2 |

2900 |

28.6

35.8

40.5 |

45 |

66

80

78 |

5.2 |

520 |

|

O |

96

160

192 |

55

50

46 |

|

21.8

27.2

30.8 |

37 |

66

80

78 |

5.2 |

450 |

|

A |

90.1

150

180 |

48.4

44

40.5 |

|

18.3

22.8

25.8 |

30 |

65

79

77 |

5.2 |

430 |

|

B |

83.6

139

167 |

41.8

38

35.0 |

|

14.9

18.5

21.0 |

22 |

64

78

76 |

2.2 |

360 |

125-80-250 |

Z |

103

172

206 |

100

92

84 |

2900 |

43.2

55.8

63.9 |

75 |

65

77

74 |

4.8 |

895 |

|

O |

96

160

192 |

87

80

73 |

|

35.0

45.3

51.6 |

55 |

65

77

74 |

4.8 |

880 |

|

A |

89.8

150

180 |

76.1

70

63.9 |

|

29.1

37.5

42.8 |

45 |

64

76

73 |

4.8 |

550 |

|

B |

83.1

139

166 |

65.3

60

54.8 |

|

23.5

30.2

34.4 |

37 |

63

75

72 |

4.8 |

475 |

125-80-315 |

Z |

100

167

200 |

145

136

129 |

2900 |

68.0

84.7

96.7 |

110 |

58

73

73 |

4.5 |

1315 |

|

O |

96

160

192 |

133

125

119 |

|

60.0

74.6

85.2 |

90 |

58

73

73 |

4.5 |

930 |

|

A |

91.7

153

183 |

121

114

109 |

|

53.1

65.9

75.3 |

75 |

57

72

72 |

4.5 |

835 |

|

B |

87.1

145

174 |

110

103

98.1 |

|

46.4

57.4

65.6 |

75 |

56

71

71 |

4.5 |

835 |

|

C |

82.4

137

165 |

97.9

92

87.6 |

|

39.9

49.1

56.1 |

75 |

55

70

70 |

4.5 |

835 |

125-100-200 |

O |

120

200

240 |

57.5

50

44.5 |

2900 |

28.0

33.6

36.4 |

45 |

67

81

80 |

4.5

4.5

5.0 |

525 |

|

A |

111

185

222 |

49.3

42.9

38.2 |

|

23.1

27.7

30.0 |

37 |

64.5

78

77 |

4.5

4.5

4.7 |

460 |

|

B |

103

172

207 |

42.6

37.1

33.0 |

|

19.2

23.2

25.2 |

30 |

62.5

75

74 |

4.5

4.5

4.55 |

445 |

|

C |

94.4

157

189 |

35.6

31.0

27.9 |

|

15.3

18.7

20.3 |

30 |

60

71

70 |

4.5

4.5

4.5 |

445 |

125-100-250 |

O |

120

200

240 |

87

80

72 |

2900 |

43.0

55.9

62.8 |

75 |

66

78

75 |

3.8

4.2

5.0 |

840 |

|

A |

112

187

224 |

75.8

69.7

62.7 |

|

35.0

45.3

52.1 |

75 |

66

78.2

73.5 |

3.8

4.08

4.6 |

840 |

|

B |

104

174

209 |

65.2

60.6

54.6 |

|

28.4

36.9

42.5 |

55 |

66

78

73 |

3.8

4.0

4.4 |

690 |

|

C |

96.9

162

194 |

65.8

52.2

47 |

|

22.7

29.5

34.0 |

45 |

66

77.8

73 |

3.8

3.9

4.15 |

575 |

125-100-315 |

O |

120

200

240 |

133

125

120 |

2900 |

72.1

90.8

102 |

110 |

60

75

77 |

5.0

4.5

5.0 |

320 |

|

A |

112

187

225 |

116

110

105 |

|

60.4

76.4

85.9 |

110 |

59

73.3

75.1 |

4.9

4.7

4.4 |

1320 |

|

B |

104

174

209 |

100

94.8

91.0 |

|

49.3

63.5

70.8 |

90 |

58

70.8

73.1 |

4.3

4.5

4.0 |

970 |

|

C |

96.5

161

193 |

85.7

80.9

77.7 |

|

39.5

51.8

57.3 |

75 |

57

68.4

71.3 |

4.0

4.2

4.43 |

865 |

上一条:OS/OSL型单级双吸离心泵

下一条:sh/S/SA双吸中开离心泵 |